How to Choose the Right Speed Reducer Gearbox for Your Application: A 2024 Expert Guide

25

2025-05

Introduction: Why Choosing the Wrong Gearbox Can Skyrocket Costs

In industrial machinery, the speed reducer gearbox is the backbone of power transmission.

However, selecting the wrong type can lead to:

Frequent breakdowns (e.g., gear wear, overheating)

Up to 20% energy waste (inefficient models drain power)

Doubled maintenance costs (mismatched loads damage bearings)

This guide combines ISO standards and real-world case studies to provide a 7-step selection framework, helping you optimize performance and slash long-term costs.

Step 1: Define Your Application Requirements

Start by analyzing your operational needs:

1.Load Type: Constant load (e.g., conveyor) vs. shock load (e.g., crusher).

Example: Mining crushers require planetary gearboxes, which withstand 3x more shock than worm gearboxes.

2.Speed Ratio: Calculate using

3.Environment: Choose IP65+ rated gearboxes for dusty, wet, or high-temperature conditions.

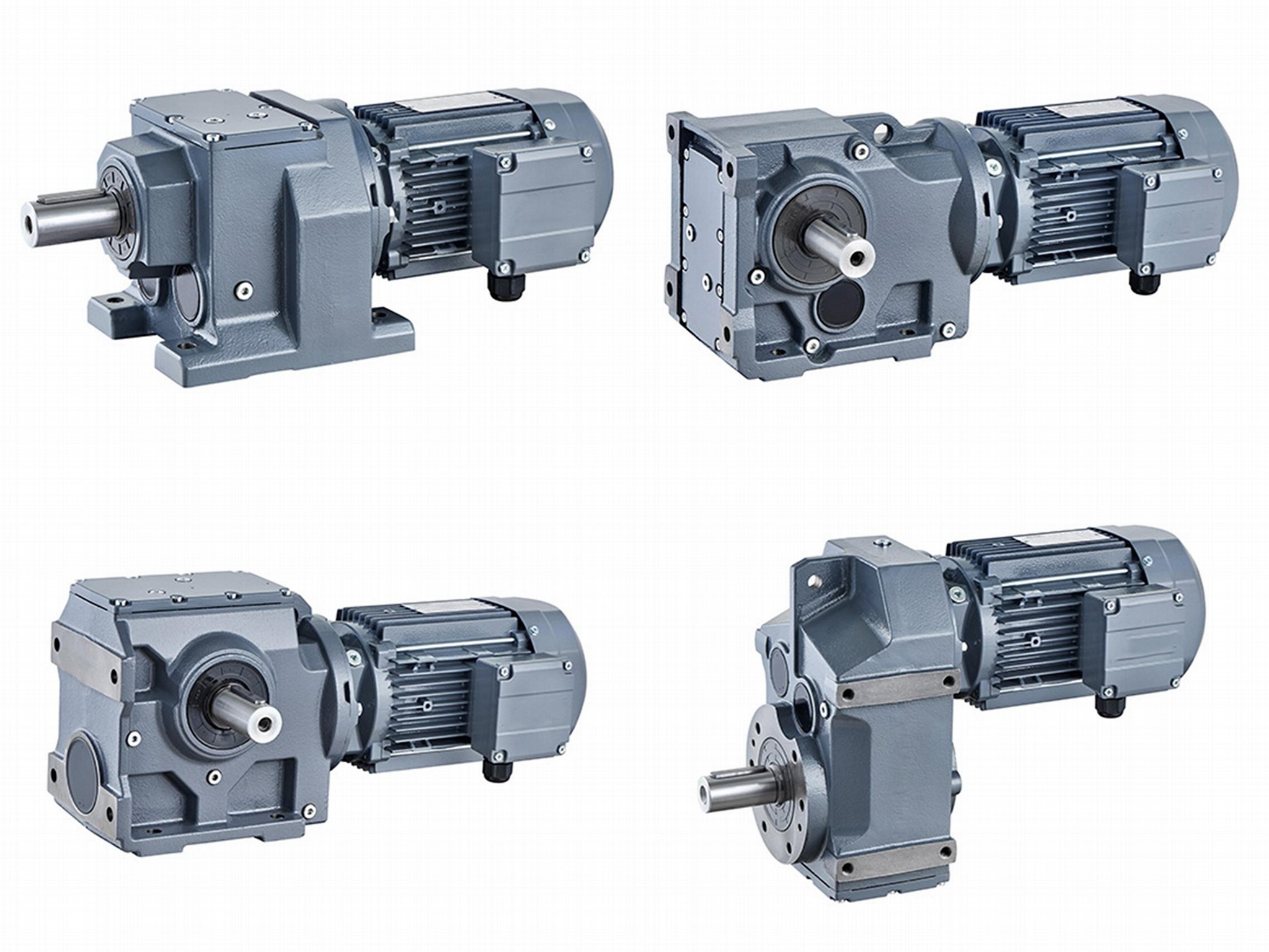

Step 2: Compare Gearbox Types and Performance

| Type | Pros | Cons | Best For |

|---|---|---|---|

| Planetary Gearbox | 95%+ efficiency, high torque | High cost | Heavy machinery, robotics |

| Worm Gearbox | Self-locking, compact | Low efficiency (60-70%) | Packaging, light loads |

| Helical Gearbox | Quiet, cost-effective | Limited torque | Food processing, conveyors |

Case Study: A food plant saved $12,000/year by switching from worm to helical gearboxes (65% → 92% efficiency).

Step 3: Calculate Torque, Power, and Efficiency

Torque Formula:T=9550xP/n

=Output torque (N·m), =Motor power (kW), =Output RPM.

Efficiency Loss: Worm gearboxes waste 15% energy as heat.

Pro Tip: Add 10-20% torque margin to prevent overload!

Step 4: Select Mounting Style and Size

Flange vs. Foot Mounting: Flange suits space-constrained setups (e.g., AGVs).

Size Matching: Use manufacturer CAD libraries

Step 5: Verify Supplier Credentials and Support

Certifications: ISO 9001-certified suppliers have 40% lower failure rates.

Warranty: Prioritize vendors offering 2+ years warranty with local spare parts.

Step 6: Real-World Case Studies – How Selection Impacts ROI

Case 1:

Issue: A cement plant replaced bearings every 6 months due to dust ingress.

Fix: Upgraded to IP67-rated planetary gearbox + enhanced seals.

Result: 3-year maintenance intervals, saving $85,000/year.

Case 2:

Issue: A logistics sorter’s worm gearbox overheated during frequent starts/stops.

Fix: Switched to helical gearbox + VFD motor.

Result: 18% lower energy use, 90% less downtime.

Step 7: 5 Must-Ask Supplier Questions

“Can you provide third-party efficiency test reports?”

“Is the gear material carburized steel or standard alloy?”

“Does the lubrication system allow maintenance-free operation?”

“Do you have local technical support?”

“Can we tour your fatigue testing lab?”

Common Myths & FAQs

Myths:

“Higher RPM needs higher reduction ratio” → Torque matters more.

“Expensive gearboxes always perform better” → Over-specification wastes budgets.

FAQs:

Q: What’s the average lifespan of a speed reducer gearbox?

A: 7-10 years under normal conditions (6,000 annual operating hours).

Q: How often should I replace lubricant?

A: Mineral oil: 4,000 hours; synthetic: 8,000 hours (per ISO 6743).