PRODUCT CENTER

Description

DCY/DBY series conical cylindrical gear reducer is a kind of external meshing gear transmission device, whose input and output shafts are perpendicular to each other. The main transmission parts of this series reducer are made of high-quality alloy steel, and the gears are treated by carburizing quenching and precision grinding process, which have the advantages of high bearing capacity, long service life, small volume, high efficiency, light weight and so on.

Technical parameters and scope of application

Maximum speed of input shaft: not more than 1500 rpm

Working environment temperature: between -40℃ and +45℃, when the ambient temperature is lower than 0℃, the lubricating oil should be heated before starting.

Gear circumferential speed: not more than 20 meters / sec.

Application field

DCY/DBY series of conical cylindrical gear reducers are widely used in various general-purpose machines, such as belt conveyors, bucket elevators, metallurgy, mining, chemical industry, coal, building materials, light industry, petroleum and other fields. They are suitable for transmission occasions where the input and output directions are arranged vertically.

Model classification

DBY: Two-stage hardened bevel cylindrical gear reducer

DBYK: Two-stage hardened bevel cylindrical gears hollow shaft reducer

DCY: Three-stage hardened bevel cylindrical gear reducer

DCYK: Three-stage hardened bevel-cylindrical gearbox with hollow shaft

Structural features

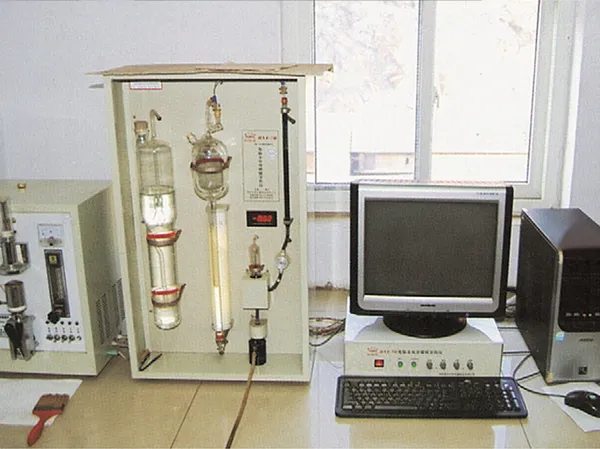

Gear material: high-strength low-carbon alloy steel carburized and quenched, tooth surface hardness of HRC58-62. tooth surface contact strength and tooth root bending strength is high.

Gear precision: up to grade 6. all gears are ground teeth process, high processing precision.

Noise level: less than 85 dB, high transmission efficiency (two-stage 96%, three-stage up to 94% or more)

keyword:

DCY/DBY series bevel cylindrical gear reducer

Production Strength

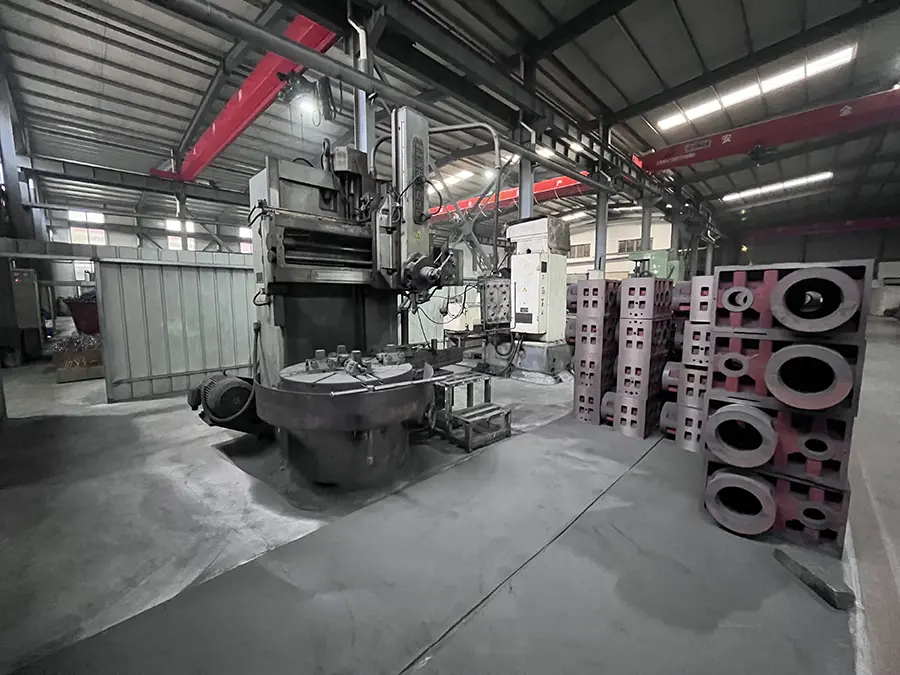

Casting and Pouring